LIGHTS-OFF ON-SITE TIMBER CONSTRUCTION: AUTONOMOUS ON-SITE PREPARATION, POSITIONING, ASSEMBLY AND GLUING OF LARGE-SCALE TIMBER ELEMENTS UTILISING A MULTI-SCALAR ROBOTIC FABRICATION SYSTEM

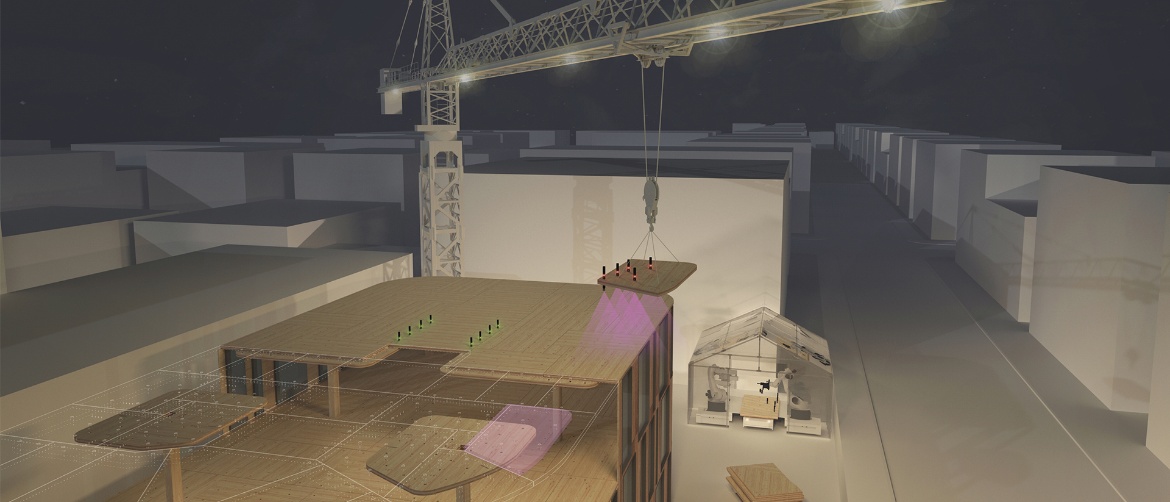

The research aims to develop core technologies for automated on-site timber construction, with a primary focus on automating the on-site positioning, joining and gluing of large-scale timber elements.

Over the last few decades, the timber construction industry has grown in importance and competitiveness through the development of digital prefabrication technologies. However, on site, these components are still largely assembled 'by hand' with limited efficiency. The aim of the project is to develop, integrate and test processes and construction systems that enable a high degree of automation on site, so that every dry hour can be used for building construction. Ideally, a construction crane on the site can lift timber components for 168 hours a week, while human assistance is limited to the traditional 40-hour working week.

To achieve this, the project explores the use of a multi-scalar robotic team to enhance traditional construction equipment with digital control systems and innovative, distributed clamping robots. The comprehensive system implementation aims to improve the construction process and expand the architectural design possibilities of timber structures.

PRINCIPAL INVESTIGATORS

Prof. Achim Menges

Institute for Computational Design and Construction (ICD), University of Stuttgart

TEAM

PARTNERS

Züblin Timber GmbH

FUNDING

Bundesinstitut für Bau-, Stadt- und Raumforschung (BBSR) im Bundesamt für Bauwesen und Raumordnung, Forschungsinitiative Zukunft Bau

PEER-REVIEWED PUBLICATIONS

OHTER PUBLICATIONS

DATA SETS