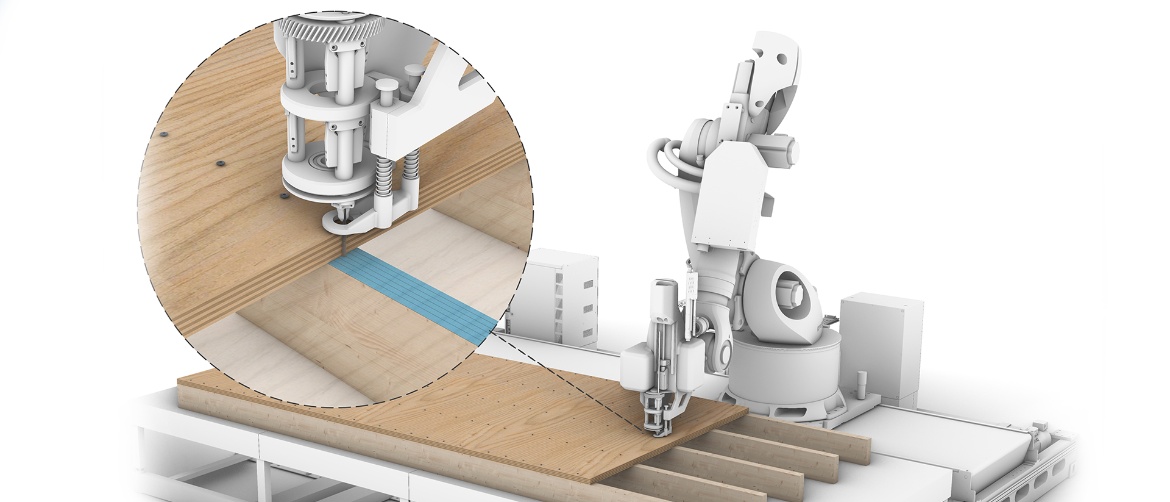

ROBOTIC SCREW-PRESS GLUING

The aim of this project is to develop the potential of timber construction within the current building inspection regulations, with a focus on the use of automated and flexible screw-press bonding methods. The competence of the applicants in both computational design and digital manufacturing methods, as well as material-specific technical knowledge, will also enable further proposals for adaptations to the building regulations to be supported by well-founded tests and exact, detailed investigations. This will allow the development of highly innovative processes with the latest materials and comprehensive possibilities for material-efficient, high-performance timber construction within the quality-assurance criteria for safe buildings. The project also aims to verify the prerequisites for application-specific manufacturing processes for robotically bonded timber joints, to discuss further development possibilities and to identify possible obstacles at an early stage. The joining processes developed in the project have the potential to find wide application in versatile building systems of the future.

In timber construction it is generally acknowledged that there is limited automation of additive production steps, such as joining and connecting wooden components into large assemblies. Industrial robots can play a key role in these spatially complex fabrication operations, as they not only have the necessary flexibility but can also arrange components with high spatial precision. Researchers at the ETH Zurich have been working on this topic for several years. Initially, wooden beams were robotically joined and nailed, which contributes to a smooth fabrication process, but poses major challenges for structural analysis. In parallel, bonded joints with epoxy adhesives have been investigated, but this still requires manual injection of the adhesive and sealing of the joint.

A similar method is currently being developed by TS3 engineers in Switzerland. This achieves flexible bonding of CLT panels by means of pressure-free and jointfilling adhesive systems that bond the CLT panels on-site. However, due to the required joint thickness, this construction method requires particularly large quantities of adhesive and additionally depends on manual work. In order to achieve the required pressure for bonding with small joint dimensions, several different processes and pressure devices are known to achieve the required pressures for bonding with small joint dimensions. Screw press bonding is the only way to work without form-restricting pressing machines, but its potential in digital fabrication has not yet been explored and brought into alignment with building codes.

The project combines explorative-empirical and systematic-technical research methods within an interdisciplinary team. The system development within the research project follows the principles of integrative, feedback-driven and interdisciplinary research. Based on fully digital design, planning and manufacturing processes, structures can be planned and manufactured that were unattainable just a few years ago.

PRINCIPAL INVESTIGATOR

Prof. Achim Menges

Institute for Computational Design and Construction (ICD), University of Stuttgart

RESEARCHERS

Tim Stark (ICD)

Tobias Schwinn (ICD)

Hans Jakob Wagner (ICD)

Aaron Münzer (MPA)

PARTNERS

Dr. Simon Aicher

Materials Testing Institute, Department for Timber Structures (MPA), University of Stuttgart

FUNDING

Bundesinstitut für Bau-, Stadt- und Raumforschung (BBSR) im Bundesamt für Bauwesen und Raumordnung, Innovationsprogramm Zukunft Bau

Projekt: „Robotische Schraubenpressklebungen: Entwicklung hochleistungs- und anpassungsfähiger, digital gefertigter Klebeverbindungen im Holzbau“, SWD-10.08.18.7-20.42

PEER-REVIEWED PUBLICATIONS

OTHER PUBLICATIONS

DATA SETS