EXTENSION OF THE CYBER-PHYSICAL PREFABRICATION PLATFORM FOR RELIABLE PRODUCTION OF LARGE-SCALE FIBRE COMPOSITE BUILDING ELEMENTS USING CONVENTIONAL AND ALTERNATIVE MATERIAL SYSTEMS

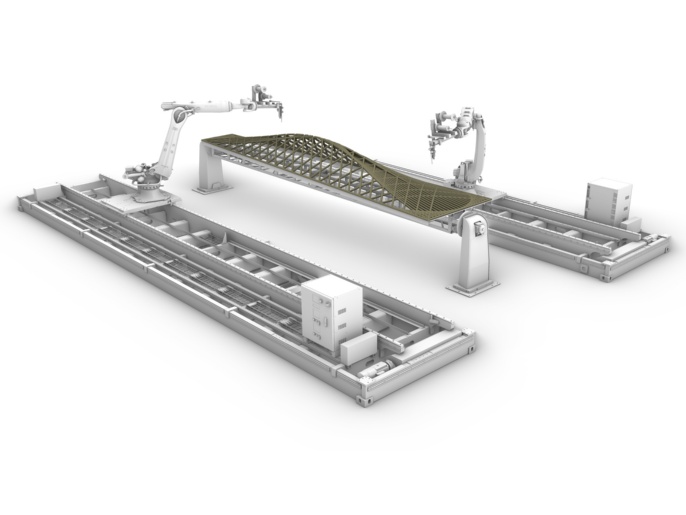

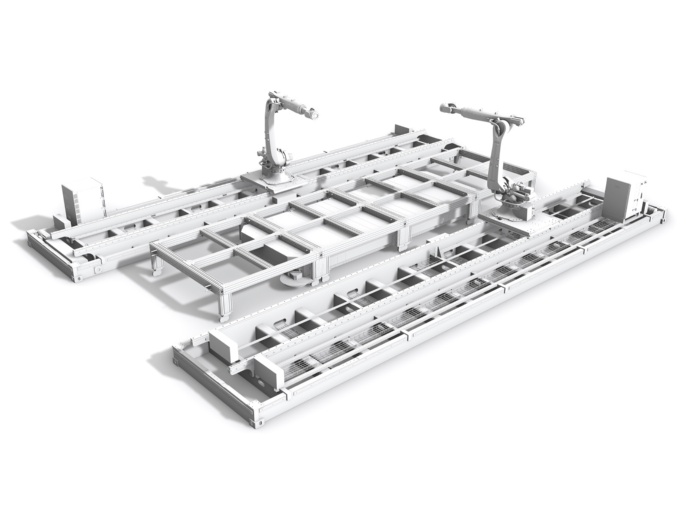

In the previous research project (RP 14-1), a fabrication system for coreless filament winding (CFW) was developed and implemented, which allows the manufacturing of fibre components of different shapes with minimal formwork. The system consists of two container platforms, each equipped with a robot on a linear axis to enable the manufacturing of large-scale building components, and a filament placement head that allows passing between robots, on-head impregnation and tension control. While previous approaches have been stationary [1], the platform developed is portable and reconfigurable.

Although the current platform already enables manufacturing of large components, it has several limitations in terms of workpiece size, production speed, possible fibre network configurations/syntaxes, process predictability (and associated safety factors), use of more sustainable materials and ease of programming. Overcoming these limitations poses scientific challenges that will be addressed in this project by investigating the extension of the fabrication platform and associated fabrication space, as well as production speed, through robot teams and autonomous mobile robots. This will be complemented by methods for path planning automation methods, the development of monitoring and compensation methods to reduce safety factors, and by the exploration of fabricating with alternative fibre/matrix systems. The developments will be tested and evaluated in two demonstrators.

[1] Bodea, S., Zechmeister, C., Dambrosio, N., Dörstelmann, M., Menges, A.: 2021, Robotic coreless filament winding for hyperboloid tubular composite components in construction, Automation in Construction, Elsevier. (DOI: 10.1016/j.autcon.2021.103649)

PRINCIPAL INVESTIGATORS

Prof. Dr.-Ing. Alexander Verl

Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW), University of Stuttgart

Prof. Achim Menges

Institute for Computational Design and Construction (ICD), University of Stuttgart

Prof. Dr.-Ing. Peter Middendorf

Institute of Aircraft Design (IFB), University of Stuttgart

TEAM

Dr.-Ing. Stefan Carosella (IFB)

Dr.-Ing. Armin Lechler (ISW)

Marko Szcesny (IBB)

Sebastian Hügle (IFB)

Timo König (ISW)

Christoph Zechmeister (ICD)

PEER-REVIEWED PUBLICATIONS

2024

- Kannenberg, F., Zechmeister, C., Gil Pérez, M., Guo, Y., Yang, X., Forster, D., Hügle, S., Mindermann, P., Abdelaal, M., Balangé, L., Schwieger, V., Weiskopf, D., Gresser, G. T., Middendorf, P., Bischoff, M., Knippers, J., & Menges, A. (2024). Toward reciprocal feedback between computational design, engineering, and fabrication to co-design coreless filament-wound structures. Journal of Computational Design and Engineering, 11(3), Article 3. https://doi.org/10.1093/jcde/qwae048

2023

- Gil Pérez, M., Mindermann, P., Zechmeister, C., Forster, D., Guo, Y., Hügle, S., Kannenberg, F., Balangé, L., Schwieger, V., Middendorf, P., Bischoff, M., Menges, A., Gresser, G. T., & Knippers, J. (2023). Data processing, analysis, and evaluation methods for co-design of coreless filament-wound building systems. Journal of Computational Design and Engineering, 10(4), Article 4. https://doi.org/10.1093/jcde/qwad064

- König, T., Verl, A., & Lechler, A. (2023). Cornuspline Path Planning Algorithm for the Fabrication of Coreless Wound Fiber-Polymer Composite Structures. IECON 2023- 49th Annual Conference of the IEEE Industrial Electronics Society, 1–6. https://doi.org/10.1109/IECON51785.2023.10312385

- König, T., Verl, A., & Lechler, A. (2023). Replication Data for: Cornuspline path planning algorithm for the fabrication of coreless wound fiber-polymer composite structures. DaRUS. https://doi.org/10.18419/DARUS-3577

- Schlopschnat, C., Pérez, M. G., Zechmeister, C., Estrada, R. D., Kannenberg, F., Rinderspacher, K., Knippers, J., & Menges, A. (2023). Co-Design of Fibrous Walls for Multi-Story Buildings. In K. Dörfler, J. Knippers, A. Menges, S. Parascho, H. Pottmann, & T. Wortmann (Eds.), Advances in Architectural Geometry 2023 (pp. 235--248). De Gruyter. https://doi.org/10.1515/9783111162683-018

- Zechmeister, C., Gil Pérez, M., Knippers, J., & Menges, A. (2023). Concurrent, computational design and modelling of structural, coreless-wound building components. Automation in Construction, 151, 104889. https://doi.org/10.1016/j.autcon.2023.104889

- Zechmeister, C., Gil Pérez, M., Dambrosio, N., Knippers, J., & Menges, A. (2023). Extension of Computational Co-Design Methods for Modular, Prefabricated Composite Building Components Using Bio-Based Material Systems. Sustainability, 15(16), Article 16. https://doi.org/10.3390/su151612189

2022

- Gil Pérez, M., Zechmeister, C., Kannenberg, F., Mindermann, P., Balangé, L., Guo, Y., Hügle, S., Gienger, A., Forster, D., Bischoff, M., Tarín, C., Middendorf, P., Schwieger, V., Gresser, G. T., Menges, A., & Knippers, J. (2022). Computational co-design framework for coreless wound fibre-polymer composite structures. Journal of Computational Design and Engineering, 9(2), Article 2. https://doi.org/10.1093/jcde/qwab081

- Gil Pérez, M., Zechmeister, C., Menges, A., & Knippers, J. (2022). Coreless filament-wound structures: toward performative long-span and sustainable building systems. In S. Xue, J. Wu, & G. Sun (Eds.), Proceedings of IASS Annual Symposia 2022: Innovation, Sustainability and Legacy (Vol. 2022, pp. 3366–3376). International Association for Shell and Spatial Structures (IASS).

- Hügle, S., Genc, E., Dittmann, J., & Middendorf, P. (2022). Offline Robot-Path-Planning and Process Simulation for the Structural Analysis of Coreless Wound Fibre-Polymer Composite Structures. Key Engineering Materials, 926, 1445--1453. https://doi.org/10.4028/p-970esd

- Menges, A., Kannenberg, F., & Zechmeister, C. (2022). Computational co-design of fibrous architecture. Architectural Intelligence, 1(1), Article 1. https://doi.org/10.1007/s44223-022-00004-x

- Wolf, M., Kaiser, B., Hügle, S., Verl, A., & Middendorf, P. (2022). Data Model for Adaptive Robotic Construction in Architecture. Procedia CIRP, 107, 1035–1040. https://doi.org/10.1016/j.procir.2022.05.104

2021

- Bodea, S., Mindermann, P., Gresser, G. T., & Menges, A. (2021). Additive Manufacturing of Large Coreless Filament Wound Composite Elements for Building Construction. 3D Printing and Additive Manufacturing. https://doi.org/10.1089/3dp.2020.0346

- Bodea, S., Zechmeister, C., Dambrosio, N., Dörstelmann, M., & Menges, A. (2021). Robotic coreless filament winding for hyperboloid tubular composite components in construction. Automation in Construction, 126, 103649. https://doi.org/10.1016/j.autcon.2021.103649

- Ellwein, C., Reichle, A., Herschel, M., & Verl, A. (2021). Integrative data processing for cyber-physical off-site and on-site construction promoting co-design. Procedia CIRP, 100, 451–456. https://doi.org/10.1016/j.procir.2021.05.103

2020

- Wolf, M., Elser, A., Riedel, O., & Verl, A. (2020). A software architecture for a multi-axis additive manufacturing path-planning tool. Procedia CIRP, 88. https://doi.org/10.1016/j.procir.2020.05.075

- Zechmeister, C., Bodea, S., Dambrosio, N., & Menges, A. (2020). Design for Long-Span Core-Less Wound, Structural Composite Building Elements. In C. Gengnagel, O. Baverel, & J. Burry (Eds.), Proceedings of the Design Modelling Symposium, Berlin 2019 (pp. 401--415). Springer International Publishing. https://doi.org/10.1007/978-3-030-29829-6_32

2019

- Dambrosio, N., Zechmeister, C., Bodea, S., Koslowski, V., Gil Pérez, M., Rongen, B., Knippers, J., & Menges, A. (2019). Buga Fibre Pavilion: Towards an architectural application of novel fiber composite building systems. In K. Bieg, D. Briscoe, & C. Odom (Eds.), Acadia 2019: Ubiquity and Autonomy, proceedings of the 39th Annual Conference of the Association for Computer Aided Design in Architecture, Texas (pp. 140--149). Acadia Publishing Company.

OTHER PUBLICATIONS

DATA SETS

2023

- Gil Pérez, M., Mindermann, P., Zechmeister, C., Forster, D., Guo, Y., Hügle, S., Kannenberg, F., Balangé, L., Schwieger, V., Middendorf, P., Bischoff, M., Menges, A., Gresser, G. T., & Knippers, J. (2023). Post-processed and normalized data sets for the data processing, analysis, and evaluation methods for co-design of coreless filament-wound structures. DaRUS. https://doi.org/10.18419/darus-3449

- Gil Pérez, M., Zechmeister, C., Kannenberg, F., Mindermann, P., Balangé, L., Guo, Y., Hügle, S., Gienger, A., Forster, D., Bischoff, M., Tarín, C., Middendorf, P., Schwieger, V., Gresser, G. T., Menges, A., & Knippers, J. (2023). Object model data sets of the case study specimens for the computational co-design framework for coreless wound fibre-polymer composite structures. DaRUS. https://doi.org/10.18419/darus-3375

- König, T., Verl, A., & Lechler, A. (2023). Replication Data for: Cornuspline path planning algorithm for the fabrication of coreless wound fiber-polymer composite structures. DaRUS. https://doi.org/10.18419/DARUS-3577