DESIGN, FABRICATION AND ENGINEERING METHODS FOR THE APPLICATION OF CURVED WOOD COMPONENTS FOR HIGH PERFORMANCE AND RESOURCE-EFFICIENT WOOD CONSTRUCTION

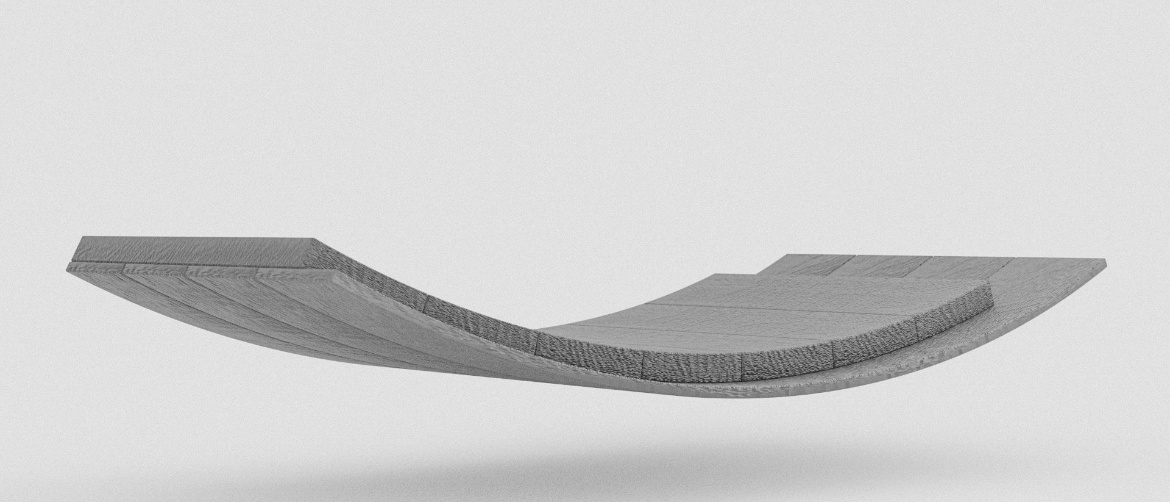

The aim of this research project is to use innovative, high curvature timber components for load-bearing, resource-efficient building structures.

The market for prefabricated timber components, in particular cross laminated timber (CLT) systems, is currently growing rapidly. These systems offer high-precision manufacturing with short on-site construction times, significantly reducing the negative impact of construction sites and waste on the environment. In timber construction, however, components are typically flat plates, straight beams or slightly curved beams. Curved components represent only a small part of the market and are a costly process that involves sophisticated wood processing, large amounts of wasted material and high machining costs. Curvature can significantly increase the load-bearing capacity of a building component while reducing the amount of material required. However, these factors have so far precluded the use of wood for high load-bearing curved building structures in favour of less environmentally friendly materials such as concrete, steel or plastics. The innovative nature of this project lies in the development and application of new, high curvature BSPH (CLT) building systems. The advantages of these systems will extend the use of timber as a fully sustainable building material.

PRINCIPAL INVESTIGATORS

Prof. Achim Menges

Institute for Computational Design and Construction (ICD), University of Stuttgart

Prof. Dr.-Ing. Jan Knippers

Institute of Building Structures and Structural Design (ITKE), University of Stuttgart

RESEARCHERS

Dr.-Ing. Dylan Wood (ICD)

Simon Bechert (ITKE)

FUNDING

German Federal Foundation for the Environment (DBU Az. 34714/01)

PEER-REVIEWED PUBLICATIONS

2021

- Bechert, S., Aldinger, L., Wood, D., Knippers, J., & Menges, A. (2021). Urbach Tower: Integrative structural design of a lightweight structure made of self-shaped curved cross-laminated timber. Structures, 33, 3667--3681. https://doi.org/10.1016/j.istruc.2021.06.073

2020

- Wood, D., Gronquist, P., Bechert, S., Aldinger, L., Riggenbach, D., Lehmann, K., Ruggeberg, M., Bugert, I., Knippers, J., & Menges, A. (2020). From Machine Control to Material Programming: Self-Shaping Wood Manufacturing of a High Performance Curved CLT Structure -- Urbach Tower. Fabricate 2020: Making Resilient Architecture, 50--57.

2019

- Aldinger, L., Bechert, S., Wood, D., Knippers, J., & Menges, A. (2019). Design and Structural Modelling of Surface-Active Timber Structures Made from Curved CLT – Urbach Tower, Remstal Gartenschau 2019. Impact: Design With All Senses Proceedings of the Design Modelling Symposium 2019, 419--432. https://doi.org/10.1007/978-3-030-29829-6 33

- Grönquist, P., Wood, D., Hassani, M., Wittel, F. K., Menges, A., & Ruggeberg, M. (2019). Analysis of hygroscopic self-shaping wood at large scale for curved mass timber structures. Science Advances, 5(9), Article 9. https://doi.org/10.1126/sciadv.aax1311

OTHER PUBLICATIONS

DATA SETS