A new research article on "A design methodology for fiber layup optimization of filament wound structural components" has been published in Structures, the Research Journal of The Institution of Structural Engineers. In this article, the researchers introduced a novel technique that integrates lamination parameters into the design of filament wound structures. The case studies demonstrated the effectiveness of their approach and the applicability of continuous shell models to analyze structures with internal gaps.

Abstract

The applications of fiber-reinforced polymer (FRP) composites extend rapidly along with the development of new manufacturing techniques. However, due to the complexities introduced by the material and fabrication processes, the application of conventional structural design methods for construction members has been significantly challenging.

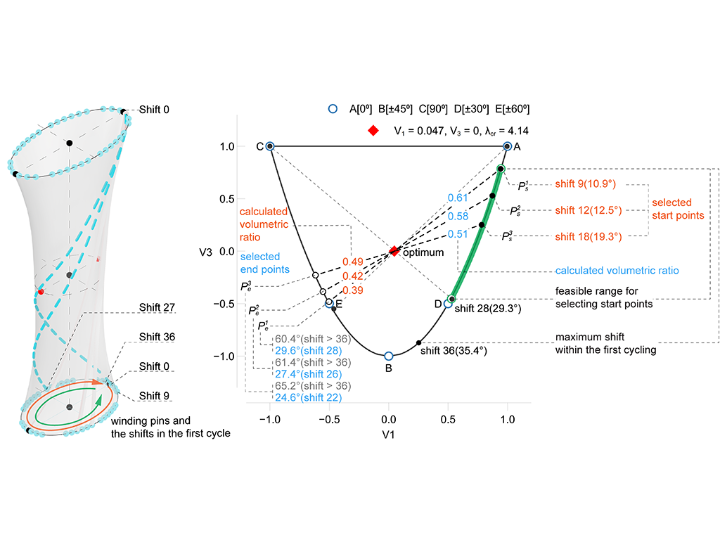

This paper presents an alternative methodology to find optimum fiber layups for a given tube-shape geometry via a graphical optimization strategy based on structural performance requirements. The proposed technique employs simplified shell element models based on classical lamination theory (CLT) to avoid explicit fiber modeling in the FEA simulations. Lamination parameters are utilized to generate the reduced stiffness matrices for continuous multi-layer FRP lamination. The fiber layup of the component is retrieved from the optimal lamination parameters that maximize the structural performance. The case study results demonstrate that the developed method provides compact solutions, linking the structural design requirements with optimal fiber orientations and volumetric proportions. In addition, the determined solutions can be interpreted directly by the winding fabrication settings.

Congratulations to everyone involved!

Please find the paper here.